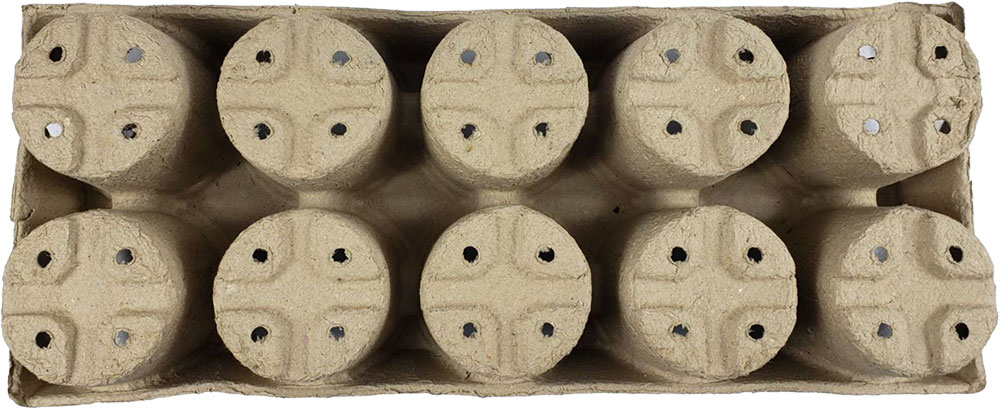

Molded Pulp

Moulded pulp, also names Molded plup or Moulded Fibre, is a packaging material, typically made from 100% recycled corrugated fibreboard and newspaper. It is used for protective packaging or for food service trays and beverage carriers. Other typical uses are end caps, trays and clamshell containers.

For many applications, Molded pulp is less expensive than expanded polystyrene (EPS), vacuumed formed PET and PVC, corrugation and forms. Molded pulp us often considered a sustainable packaging material, as defined by the Sustainable Packaging Coalition, since it is produced for recycled materials, and can be recycled again after its useful life-cycle.

BENEFITS OF PULP MOLDED PRODUCTS

Protection:

- Absorbed Impact

- Superior protection from vibration and shock

- Soft surfaces reduce scratching or abrasion

- Unaffected by temperatures

- Reduces storage space and transport with stackable products

- Static Neutral

- Configures to any complex or single shape

Cost:

- Reduce labor – no assembly required

- Lower unit cost compared to other forms of packaging

- Lower tooling cost

- Price fluctuations are minimal because pulp molding is not linked to gas, oil resin prices.

- Lower cost of disposal

Environment:

- Produced with 100% post- consumer waste

- 100% Biodegradable

- Recyclable in curb-side collection programs

- Minimal Energy used to create